Sustainably Grown Bamboo Resources

Our bamboo is sourced from responsibly managed forests, where mature bamboo is carefully cultivated to ensure stable quality, strength, and long-term sustainability from the very beginning.

Learn More

Our bamboo is sourced from responsibly managed forests, where mature bamboo is carefully cultivated to ensure stable quality, strength, and long-term sustainability from the very beginning.

Learn More

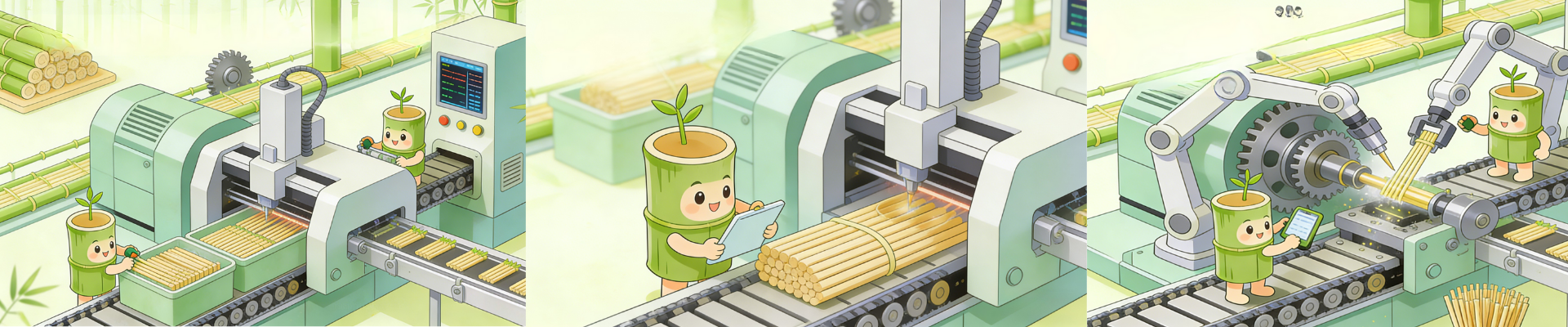

Equipped with advanced automated machinery, our production facilities operate under standardized processes to achieve high efficiency, precise control, and consistent product quality.

Learn More

From bamboo skewers and incense cores to coffee stirrers, each finished product reflects our strict quality standards, smooth craftsmanship, and readiness for global markets.

Learn More